MORE THAN 20 YEARS

Focus on Water Treatment Valve and Valve Parts Production

Zhejiang Zhongguan Valve is located in Yongjia, Wenzhou, Zhejiang, the hometown of pumps and valves. Since its establishment, it has more than 10 years of experience in professional butterfly valve production and has good cooperation with domestic and foreign customers. The butterfly valves it produces can be divided into: wafer, lug, U-Section, flange, butterfly valve and the main production diameter is from DN40 to DN1600 (if a larger size is required, please contact our sales.) The butterfly valves we produce have been well received by domestic and foreign customers for their cost-effectiveness, exquisite appearance, and excellent quality.

Professional equipment and team

Good product quality and high efficiency

Innovation, struggle and struggle

Sincerely serve every customer

First, think about the most common faucet in your home, or the old-fashioned iron disc valve you have seen. The piece (disc) of that switch is threaded through a shaft (valve stem) in the center. When it's opened or closed, that disc rubs against the sealing ring, just like rubbing an eraser against a table. Over time, it will definitely leak.

View More

Once the medium is defined, the next step is to determine the valve's primary function. Is its main purpose simply to start and stop flow (on/off isolation)? If so, ball valves, gate valves, and plug valves are excellent choices due to their tight seal.

View More

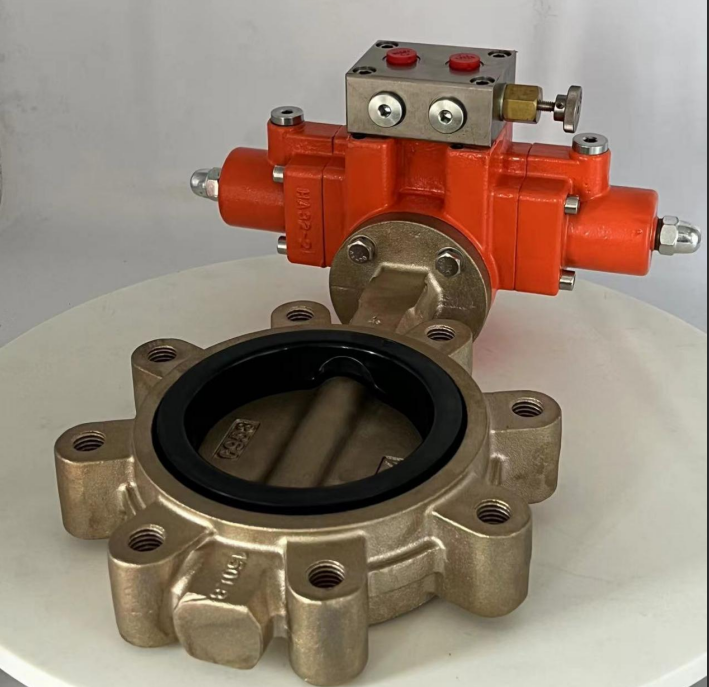

Aluminum bronze valve: Its main material is copper, combined with alloys formed by melting aluminum, iron, and other elements. Therefore, it has a kind of rustic brass color. Because it contains copper, it inherently possesses some of the properties of copper, such as corrosion resistance and good toughness.

View More

Directional valve: It's just a "fork in the road" where you want the oil to go (some can be manually operated, while others can be automatically changed by pressing a button)

View More

Recently, two newly developed ball valves by Zhongguan Valve Company have been officially put into production and are now being shipped domestically and internationally.

View More

In a large-scale water treatment project, Zhongguan Valve Co., Ltd.In a large-scale water treatment project, Zhongguan Valve Co., Ltd. provided the client with multiple electric butterfly valves, which were applied in the raw water transportation and filtration system.

View More

In the midst of the scorching summer heat, the temperature soared to over 38℃ in many areas. However, within the production base of Zhongguan Valve Co., Ltd., workers remained steadfast in the face of the high temperatures, racing against time to complete the production tasks of key products such as butterfly valves, gate valves, and ball valves, ensuring the timely delivery of orders to domestic and foreign customers.

View More

After two decades in the valve industry, I've seen plants waste millions on oversized gate valves and high-maintenance ball valves when a simple Butterfly Valve would have done the job better. The ZHONGGUAN VALVE team has helped hundreds of facilities cut costs by switching to our engineered Butterfly Valves - but what exactly makes them the smart choice for flow control?

View More

In the world of valves, two key valves with "ball" in their names—ball valves and float valves—are often confused. Although both have the "ball" in their names, their functions, applications, and operating principles are completely different. Choosing the wrong valve can lead to equipment failure or even safety accidents. As core components of fluid control systems, the differences between the two directly impact industrial safety and domestic water stability.

View More

What Differences Among Wafer Lug and Flange? You can find a brief introduction in here. If you have any more problem. please leave your message to our sales. they will help you solving problem.

View More

After twenty years of working in the valve industry, I have witnessed too many losses caused by metal valve corrosion in chemical plants. Last year, I was impressed by the case of a certain electroplating plant in Zhejiang Province. After they replaced the Zhongguan PVC Material Ball Valve, they not only solved the long-standing corrosion problem, but also saved nearly 200,000 yuan in maintenance costs each year.

View More

The butterfly valve commonly divided in to these two general types, Concentric is sealed by the rubber, according to the rubber type it can be suitable for many substances, like water, or some chemical. But it usually used in below PN 16. Eccentric butterfly valve include the double or triple eccentric/offsets, the disc achieves a “cam-like rotation” during opening and closing, completely eliminating frictional wear. Taking the triple offset structure as an example, the valve stem axis forms a compound angle with the sealing surface, ensuring zero leakage even under high temperature and high pressure conditions.

View More

Cast steel butterfly valve: "Flow Switch" in Industrial pipelines

View More

Recently, our company has successfully completed the production of the orders set by the customers and has successfully packed and dispatched the goods to the countries where the overseas customers are located. This batch of orders mainly includes butterfly valves and gate valves, providing services for the market where the customer is located.

View More

When the gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, only rely on the medium pressure to press the sealing surface of the ram to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing.

View More

There are various types of control valves, and their applicable occasions are different, therefore, the type of control valve should be reasonably selected according to the requirements of the process production process.

View More

The article is mainly talking about the types and types of control valves in the power industry

View More

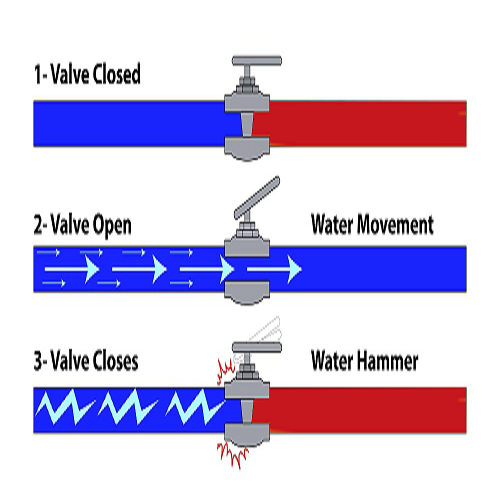

Water hammer or hydraulic shock occurs in industrial piping systems when liquid that is flowing quickly is abruptly stopped or redirected. Water hammer happens during an instantaneous change in flowing and presents as a very high-pressure spike that rushes through the pipeline, has an audible sound, and can damage components such as pipes, valves, pumps, and instruments. More specifically, fast-acting valve operation (ball, butterfly and plug) caused primarily by the speed of operation.

View More

There are many domestic manufacturers of gate valves, and most of the connection sizes are not uniform. It is mainly divided into the following categories

View More

The article is mainly introducing the content of selection Criteria For Check Valves

View More

ISO5211 is an important standard set by the International Organization for Standardization (ISO) for connecting valve actuators to industrial valves. Its main goal is to make sure that part-turn valves (like butterfly valves and ball valves) and actuators are compatible and can be easily interchanged worldwide. The standard clearly defines the dimensions of flange connections, torque requirements, hole patterns, and drive structures.

View More

The butterfly plate of the butterfly valve is installed in the diameter direction of the pipe. The butterfly valve has a simple structure, small size, light weight, only a few parts, and only needs to rotate 90° to quickly open and close, simple to operate, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the resistance of the medium when it flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics.

View More

The article is mainly talking about the features Of Butterfly Valves

View More

When it comes to industrial valves, the quality and longevity of the coating applied to the valve’s surface are critical factors that affect both its durability and performance. Valve coating thickness plays a vital role in protecting valves from corrosion, abrasion, and wear, which can otherwise lead to premature failure and costly downtime. In this article, we will explore why coating thickness is so important, and how it directly impacts the valve’s effectiveness in harsh environments.

View More

We are excited to announce our participation in Vietwater 2025! This premier event will take place from Oct 22-24, 2025, at the Saigon Exhibition & Convention Center (SECC) in Ho Chi Minh City. (The show is organised by Informa Markets Vietnam to offer an unlimited business opportunity for all companies who works in water, wastewater treatment industry in Vietnam and beyond. The event will be co-located with WETV – Vietnam’s Leading Transportation, Waste Treatment and Environment Technology Event.)

View MoreFor inquiries about butterfly valve, check valve, ball valve or price list, please leave your email to us and we will be in touch within 24 hours.