There is a fluid control device (Customized Check Valve) that automatically opens and closes through the flow of the medium itself.

Zhongguan check valve is mainly used to prevent the backflow of the medium in the pipeline system, ensure the one-way operation of the process flow and avoid equipment damage. Its core function is to rely on the medium pressure to push the valve disc to open. When the flow direction is reversed or the pressure disappears, it can be quickly closed by gravity, spring force or reverse fluid action to form a reliable one-way barrier.

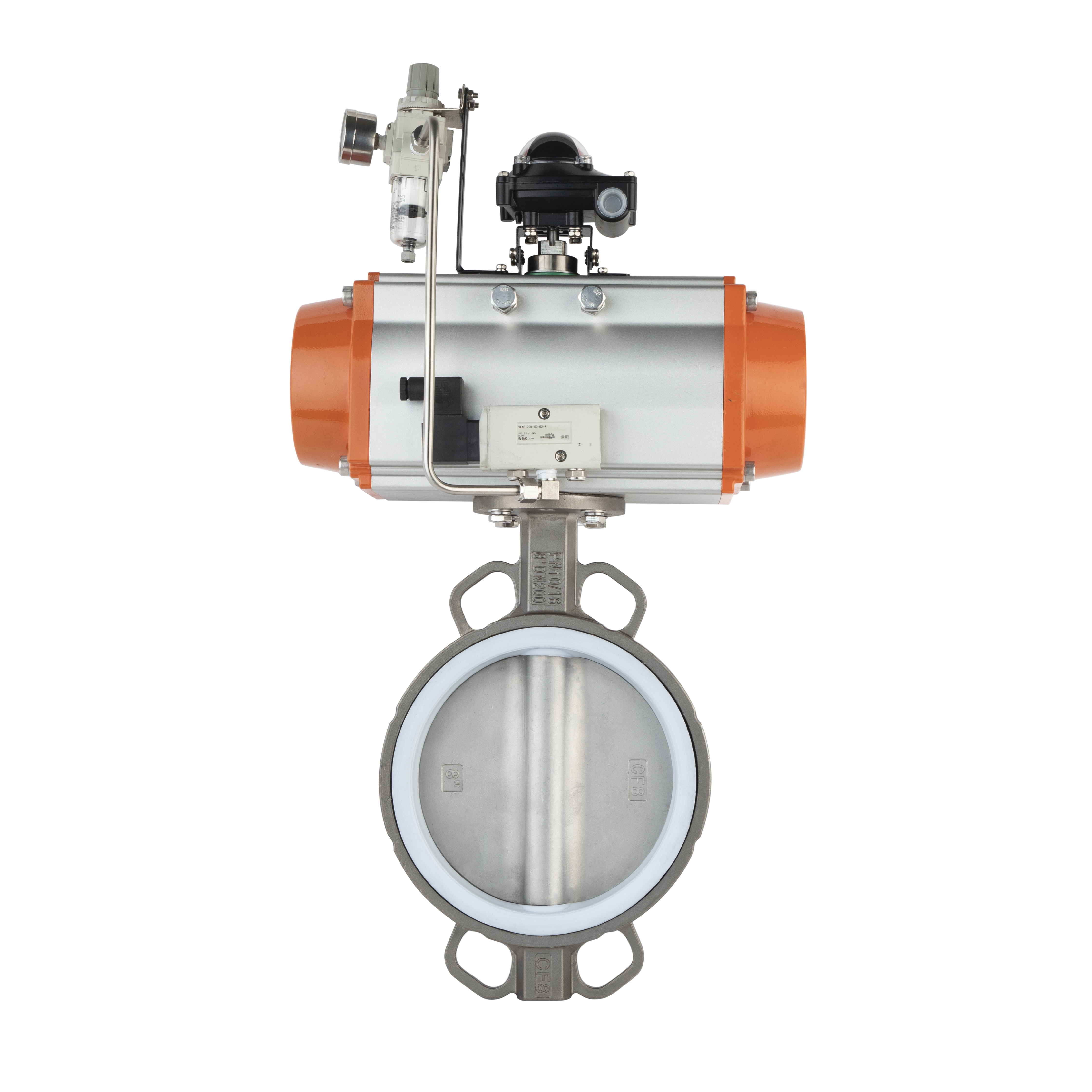

This type of valve is widely used in petrochemical, water supply and drainage systems, electric power, HVAC engineering and industrial equipment. It can be installed independently or used in conjunction with pumps, compressors and other equipment to effectively maintain the stability and safety of the system. Modern check valves mainly present various forms according to the structural principle, including lifting type using vertical motion seal, swing type using rotary structure, butterfly type with adjustment function and spherical design that adapts to high flow rate.

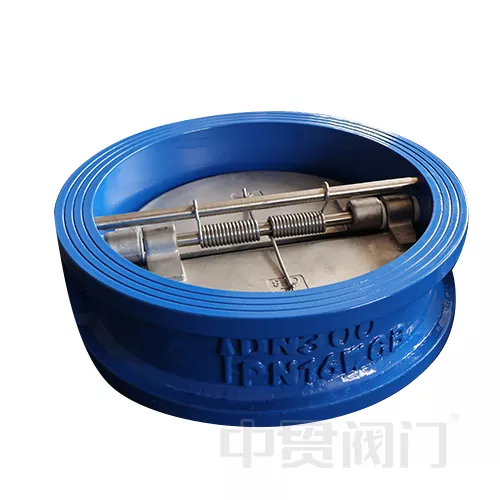

At the same time, special variants such as double plate type and inclined disc type are derived to meet the needs of different working conditions. The valve body material covers cast iron, stainless steel, copper alloy and special engineering plastics. The sealing surface can be metal hard seal or rubber soft seal. When selecting, it is necessary to comprehensively consider factors such as medium characteristics, pressure level, temperature range and installation space. Advanced manufacturing technology also gives it additional functions such as slow closing silencing and low water hammer protection, making it an indispensable basic component in modern fluid control systems.